Delta Destemmer E2-E10

Grapes are introduced through the hopper and are progressively brought into the destemmer at speed rate required without any impact. The cage and the shaft rotate in the same direction to prevent any shearing effects on the grapes.

Interchangeable cages Various cage diameters (22 mm, 25 mm or 32 mm)

Delta E2: 4-15 T/h

Delta E4: 15-25 T/h

Delta E6: 25-40 T/h

Delta E8: 40-75 T/h

Delta E10: 75-110 T/h

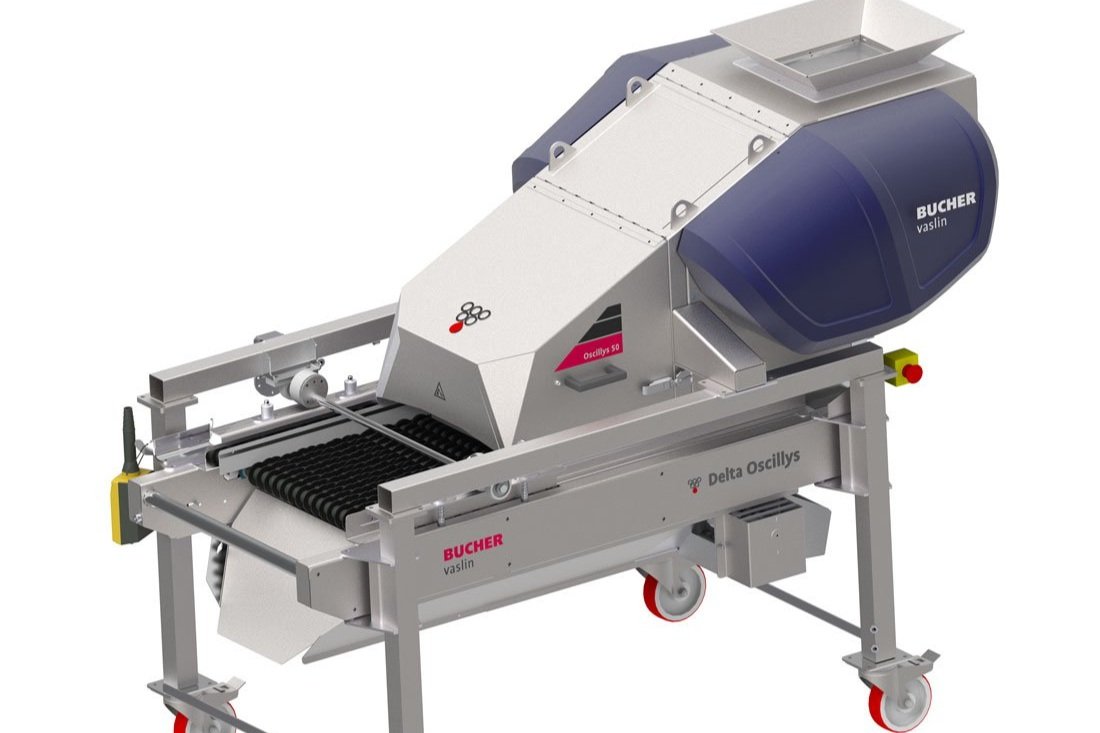

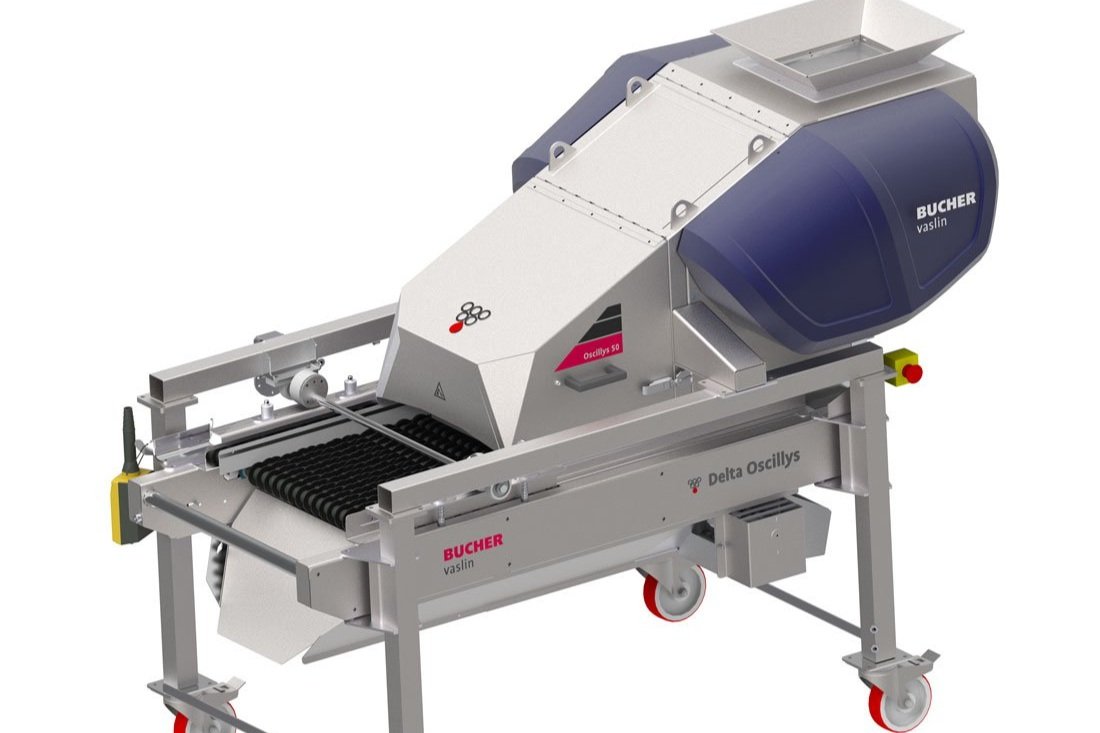

Delta Oscillys

Oscillys destemmer operates without any rotating shaft or cage to avoid mechanical interaction with clusters to avoid the creation of MOG and eliminates stem shear. The Oscillys destemmer uses an ample swinging motion of one or two cages to separate the grapes from the stems by inertia.

Preserves integrity of the berries (thus limiting production of juice and green characters).

No break or grinding stems.

Full separation of the grapes from the stems.

Elimination of shot berries, verjus, dry grapes, and unripe grapes all whom remains on the stems.

Delta Oscillys 50: up to 6 T/h

Delta Oscillys XM: up to 15 T/h

Delta Evolution

Bucher Vaslin has developed a new destemming concept for superior protection of the most fragile grape varieties. The objective is to separate grape berries from MOG while keeping their integrity throughout the operation for a minimum juice release.

Delta Evolution 2: up to 18 T/h

Delta Evolution 4: up to 30 T/h

Delta F Crusher

The Delta FC/F crushers can be combined with destemmers (Delta Evolution).

The support bars offer the choice of two different positions. The lower position allows you to place the crusher on a pump. The upper position makes it possible to position the crusher in a 500 mm diameter tank door. The gap between the rollers can be adjusted using knobs with a view of the spacing. These one-piece rollers have no retention area between the modules.